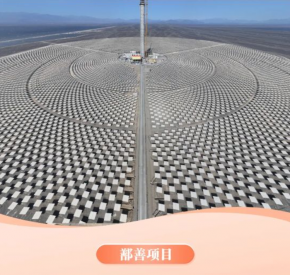

Volateq has successfully deployed faster drone scans to inspect ball joints in a 100 MW solar plant.

The firm is addressing the challenge of staying on top of O&M with a drone-based inspection system capable of scanning an entire solar field in one hour, with results delivered within just another hour.

For several months, the company has been conducting weekly inspections at CSP power plants with a total capacity of 100 MW. These inspections have demonstrated that monitoring all ball joints can be performed two orders of magnitude faster than a manual inspection would require. Founder Christoph Prahl believes their approach is both novel and relevant for the CSP community, given that ball joint failures are a major safety concern in trough CSP plants.

“So you’d have hundreds of kilometers for a human being to walk or drive across the solar field to check every single ball joint assembly,” he explained in a call from Spain.

“It’s basically a manual inspection solution, looking for evidence of friction or even for noise, because increased friction, as you may have experienced from your old car or bicycle, comes along with with strange noises. So it’s a very complicated process.”

A spatially dispersed mechanical risk

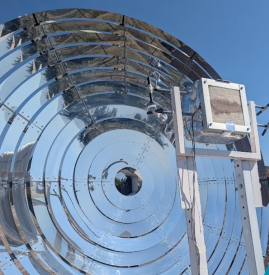

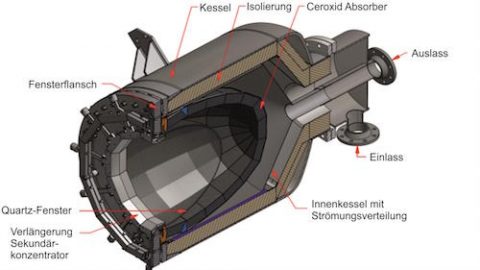

In parabolic trough systems, collectors rotate continuously to track the sun. At the focal line, a receiver tube conducts heat transfer fluid (HTF). At the end of each collector section, the rotating receiver tube connects to a fixed header piping that transports heated HTF to the power block.

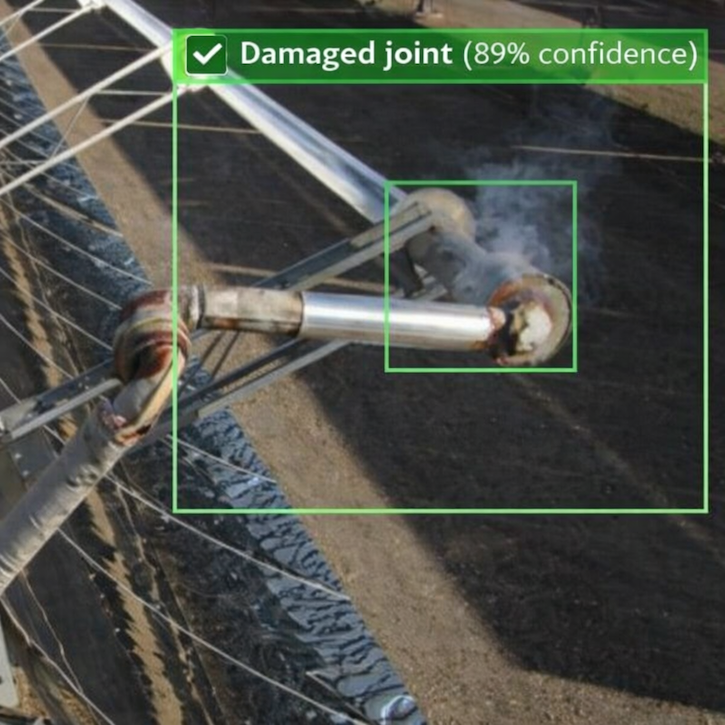

This interface between these moving and fixed components is realized through “ball” joints. Over time, friction at these joints increases due to mechanical wear. If degradation progresses, leaks or blockage can occur.

A typical 50 MW parabolic trough plant spans several square kilometers and contains approximately 600 collectors with ball joints interconnection — around 900 ball joint assemblies requiring periodic inspection.

Manual inspection requires technicians to walk or drive extensive distances across the solar field, checking each assembly for visual signs of wear or abnormal friction, sometimes also listening for acoustic anomalies that may indicate mechanical resistance.

The manual process is dangerous, labor-intensive, time-consuming, and not always sensitive to early-stage failure.

Environmental and Operational Implications

Their focus is less related to performance failure, and more on environmental and financial risks, because parabolic trough systems almost always use Therminol or similar synthetic oils as HTF. These fluids are hazardous if released into the environment.

A leak has serious consequences: enormous environmental damage (and the associated loss of reputation), clean-up measures, replacement of components, and weeks of downtime for the affected loops. From an asset management perspective, early detection is therefore much more valuable than reactive repair.

From Performance Optimization to Risk Monitoring

Volateq’s three founders met a decade ago as solar engineers at Plataforma Solar de Almería (PSA) and DLR. Their early drone research focused on optical performance optimization, identifying alignment issues, or general concentrator geometry and mirror shape.

After founding Volateq in 2020 and engaging more closely with plant operators and O&M teams, the company shifted its focus. Industry discussions highlighted cost reduction, safety, reliability, and maintenance efficiency as higher priorities than performance gains. Ball joint monitoring emerged as a high-impact application where automation could directly reduce operational risk.

“At PSA we also were working on solar plant inspection with drones, but focusing more on performance related issues and less on security related tasks,” he noted.

“But since we established the company, we were talking more with the industry, and that also has shifted a little bit our focus. Our experience with PSA and researchers was focused on performance, squeezing out the last percent of performance of the solar field. But now that we are in contact with daily operation O&M, we talk to the operators, we try to find out what is the pattern that their team is recognizing in the solar field, what triggers an alarm? As soon as we think that it’s detectable in visual or infrared images, we design a specific flight path, and the drone basically lifts off against the entire plan, comes back, and we evaluate the images, and then we can give for any component, for any ball joint assembly feed back to the operator within less than an hour to say, well, the rest is okay, but these ones look suspicious.”

Drone Platform and Inspection Workflow

The system replaces routine manual field checks with automated drone flights following predefined paths. Volateq relies on off-the-shelf prosumer drones such as the DJI Mavic 3, enabling cost-efficient deployment without custom hardware development.

For accurate and repeatable inspections, RTK (Real-Time Kinematic) positioning is indispensable. High positional precision ensures that collected imagery can be reliably assigned to specific components within the solar field’s digital twin.

Flights are conducted at relatively low altitudes — typically 10 to 15 meters — to achieve sufficient spatial resolution for detecting visual anomalies associated with increased friction or early leakage. The company works with operators to define detectable signatures in optical and infrared imagery. While acoustic indicators remain outside the scope of drone sensing, other indicators manifest visually and can be captured effectively.

Once deployed, the drone autonomously scans the entire solar field along its predefined route. After landing, image data are uploaded to Volateq’s web-based platform for analysis. Within less than an hour, operators receive a structured assessment identifying specific ball joints that appear suspicious. Instead of manually verifying thousands of components, O&M teams receive a prioritized short list for targeted inspection and further measures.

The analysis mainly includes visual indicators such as vapor clouds or geometric anomalies, which may indicate unusually high friction.

Time Reduction and O&M Impact

At deployment sites, a complete inspection cycle requires approximately one hour of flight time and one additional hour for data processing and upload. Compared with conventional manual inspections (which typically involve multiple personnel and extended site access), this represents a significant reduction in time and logistical effort.

For large parabolic trough facilities with thousands of distributed mechanical interfaces, inspection efficiency directly affects operational risk management. Shorter inspection cycles enable more frequent assessments and earlier identification of emerging issues.

As CSP plants mature under increasing cost pressure, digital inspection tools are becoming integral to routine O&M strategies. Volateq’s deployment illustrates how drone-based monitoring can evolve into a practical solution for improving safety, reliability, and maintenance planning.