The 510 MW CSP project at Ouarzazate in Morocco, NOOR I,II,II comprises both forms of CSP. Tower CSP (NOOR III) is seen here in the foreground while behind it, rows of parabolic troughs – the two Trough CSP plants (NOOR I and II) – can be seen further back.

In solar thermal energy, all concentrating solar power (CSP) technologies use solar thermal energy from sunlight to make power. A solar field of mirrors concentrates the sun’s energy onto a receiver that traps the heat and stores it in thermal energy storage till needed to create steam to drive a turbine to produce electrical power.

Thermal energy storage

Thermal energy storage. is integral to CSP because it enables this heat-based form of solar to generate electricity at night and during cloudy periods, so it is a flexible and dispatchable form of solar energy. In current commercial projects liquid molten salts store the heat at up to 600ºC but new thermal energy storage materials are being investigated, gases like air, liquid metals and solids like ceramics such as sand or Bauxite. Materials that can attain higher temperatures have resulting efficiency gains leading to lower costs.

See How CSP’s thermal energy storage works.

Basic summary of the four CSP technologies:

There are four types of CSP technologies: The earliest in use was trough, and the predominant technology now is tower. This is because tower CSP can attain higher temperatures, resulting in greater efficiency.

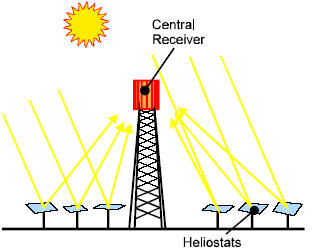

Tower Systems:

Power tower or central receiver systems utilize sun-tracking mirrors called heliostats to focus sunlight onto a receiver at the top of a tower. A heat transfer fluid heated in the receiver up to around 600ºC is used to generate steam, which, in turn, is used in a conventional turbine-generator to produce electricity. The National Renewable Energy Laboratory (NREL) maintains the global Tower deployment database.

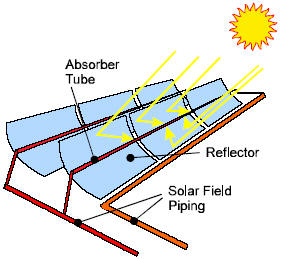

Parabolic Trough Systems:

In a parabolic trough CSP system, the sun’s energy is concentrated by parabolically curved, trough-shaped reflectors onto a receiver pipe – the heat absorber tube – running along about a meter above the curved surface of the mirrors. The temperature of the heat transfer fluid flowing through the pipe, usually thermal oil, is increased from 293ºC to 393ºC, and the heat energy is then used in the thermal power block to generate electricity in a conventional steam generator.

A trough solar collector field comprises multiple parabolic trough-shaped mirrors in parallel rows aligned to enable these single-axis trough-shaped mirrors to track the sun from east to west during the day to ensure that the sun is continuously focused on the receiver pipes. Trough deployment database.

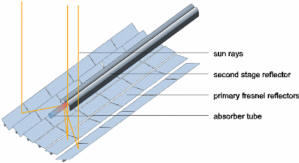

Linear Fresnel Systems:

Similar to the long arrays of a parabolic trough CSP system, a Linear concentrating collector field consists of a large number of collectors in parallel rows. These are typically aligned in a north-south orientation to maximize annual and summer energy collection. The mirrors are laid flat on the ground and reflect the sunlight to the pipe above. Like trough and tower, Fresnel can also incorporate storage in a power block, or generate steam for direct use. Fresnel deployment database.

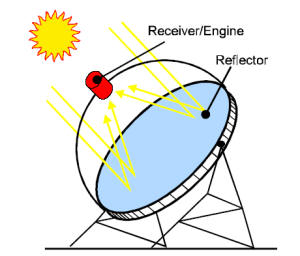

Parabolic Dish Systems:

A Parabolic dish system consists of a parabolic-shaped point focus concentrator in the form of a dish that reflects solar radiation onto a receiver mounted at the focal point. These concentrators are mounted on a structure with a two-axis tracking system to follow the sun. The collected heat is typically utilized directly by a heat engine mounted on the receiver moving with the dish structure. Dish can attain extremely high temperatures, and holds promise for use in solar reactors for making solar fuels which require very high temperatures. Stirling and Brayton cycle engines are currently favored for power conversion, although dish has been seldom deployed commercially for power generation. Dish deployment database.

For more information: