A team of solar researchers in Greece is contributing to the development of a technology to produce bio-crude from mixed wet waste processed onsite in a mobile solar-heated reaction chamber. They have innovated the use of concentrated solar thermal (CST) energy to heat this process using hydrothermal liquefaction (HTL) to produce bio-crude, a thick oil that can be refined into various liquid fuels.

The chemistry involved in HTL is not novel, but heating the HTL process using CST has had only limited research. Their experiments showed solar heat performs measurably better than the traditional HTL processes, which require energy-intensive high pressure. It’s an idea whose time has come.

“We make use of something that is technically a waste – and non-recyclable waste in most cases – and we transform it into something that has an added value,” explained lead researcher Nikolaos Tsongidis, whose team at the Centre for Research & Technology Hellas (CERTH), has been contributing to the advancement of the prototype since 2018.

“The main difference in this technology is we use highly moist biomass. We don’t have to dry the biomass first like the other technologies do, which is energy-intensive and thus costly. This technology has been studied in the past but not implemented much because it had some barriers, like covering the necessary thermal requirements, but the addition of CST is what has now created some new potential.”

A mobile solar processing unit is able to serve small waste generators

The team plans to process the wet waste on-site at small Greek orchards, food processors, paper mills, and other factories. Many small orchards and industries produce wet waste, but their small size makes it inefficient to transport their material to a central processing facility.

While each producer might be small, there are so many of them in Greece that they represent a missed opportunity that has not yet been addressed.

“Our idea was to move from place to place and treat the biomass on site so the industry does not have to transport all the biomass into a specific place,” Tsongidis explained. “We have designed and constructed a mobile platform where we put all the several different components of the process. So we can move it from place to place, even operating off-grid.”

This mobile unit is about the size of an oil tanker truck, 3 m tall, and topped by a 4 m long parabolic trough solar collector. Once the tanker processes the wet waste on site, it drives its liquid bio-crude to a central refinery, where it can be further refined to liquid hydrocarbons like gasoline and aviation fuel. After unloading its bio-crude, the tanker truck drives back to the sources of the raw materials to load up once again.

The wet waste processing would be done in a reaction chamber in batch mode heated by solar energy collected in the solar receiver along the top. The team has so far tested a temperature range between 350 and 450 °C with a reaction pressure ranging from 200 to 300 bar and a retention time of 30 minutes.

“What we obtain from our process is an intermediate product, a bio-crude,” he said.

“We first depolymerize and then repolymerize the organic matter, and what we obtain is an intermediate product which needs to be further upgraded by hydrogenation into either a sustainable aviation fuel like SAF or into marine fuels or whatever kind of fuels a refinery wants to achieve, while we even produce sidestreams of biochar or an aqueous phase that can be potentially used as fertilizer or recycled in the HTL process if needed. We have managed to build and operate batch reactors and demonstrated that we can produce approximately 10 liters of biofuel per hour, so this is not lab scale, but semi-pilot scale.”

Combining food waste with plastic waste

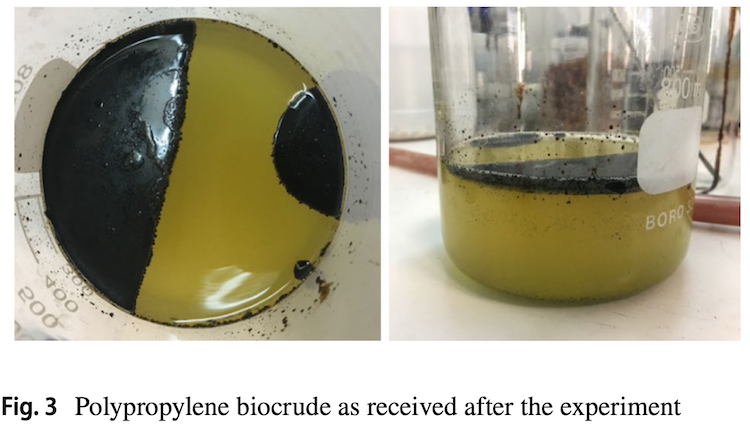

They can mix wet food waste with waste from non-recyclable plastics, like polyethylene (PE) and polypropylene (PP).

They found that including these two plastics in the HTL process improves the bio-crude yield and reaction mechanisms. Hydrogen and carbon can already be extracted from agricultural and other wet waste, such as manure and algae, to make bio-crude using HTL. However, including the plastic waste allowed them to extract more valuable oils and chemicals, making the entire process more efficient and beneficial.

“We regard all these different kinds of waste as exploitable or even valuable organic waste,” Tsongidis noted.

“No matter if they were plastics or dairy or whatever in their previous life, they are all organic matter. It’s not too chemically different whether they’re made of oil pits and paper waste or corn cobs and plastics. We have tried many, many different kinds of waste, especially waste that cannot be recycled.”

Mixing for ideal moisture content

Testing various moisture levels revealed that moisture content above 90% proved to work best. Water acts as both a solvent and a reactant near its sub-/supercritical point (374oC, 220 bar). So they aim to combine a source of wetter waste with more solid waste to keep the moisture content at an optimal level.

“We first analyze what content of carbon, hydrogen and nitrogen our feedstock has. And the higher heating value is also measured in our lab,” he said.

“So we have a data set where we have all the relative data, and then we decide which different feedstocks can be combined in order to obtain the desired product and the desired result. Dairy waste always has like 90% of moisture while peach stones have like 5 or 6%. So we mix them in order to attain a very high moisture content.”

This moisture content in fruit and vegetable waste can also vary by season, so over the year, they seek out alternative kinds of feedstocks to keep the moisture content consistent year round.

Next – expanded team to include thermal storage

The team has tested all the component parts of their system. Currently they can run up to six or seven hours, during sunlight. To be able to run around the clock, they could increase the daily output, with two modular reactors run one after the other. So they have begun investigating adding storage, using a solid media like ceramic particles. For this effort they are looking to add expertise in thermal energy storage in collaboration with their project partners.

“We have just kick-started the ignition phase of an acceleration program in our EU-funded project called SolarHub (G.A. 101086110), where we will be seeking research groups or people who want to contribute in the field and receive mentoring support and potential access to funding. Two additional acceleration rounds will follow in the next few years” said Tsongidis. More details regarding the ignition phase of the acceleration program can be found here: https://solarhub.meetinghand.net/en/4741-solarhub-accelerator-program

“We invite them to give us some ideas and solutions and be part of the acceleration program that we will be working on. So this is something that has just started and is very fresh.”

Further reading:

Valorization of Plastic Waste: A Lab-Scale Approach with the Aid of Solar Hydrothermal Liquefaction Technology https://doi.org/10.1007/s12649-022-01837-3

Designing Solar Furnaces to Make Biochars without Air Pollution

Absolicon Investigates Wastewater Sludge Drying with 140°C Solar Heat