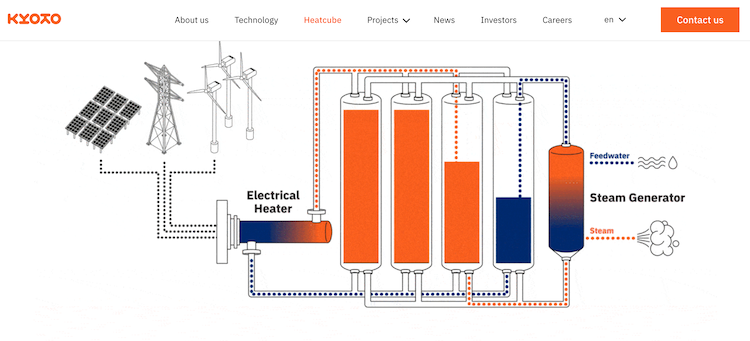

Heatcube tanks of molten-salts ©Kyotogroup

Why standalone thermal energy storage has heated up

It became apparent as CSP was commercialized that the low cost and durability of the thermal energy storage was its key advantage. Thermal energy storage makes it possible to deliver solar around the clock by storing solar as heat during the day and discharging the heat as steam to produce thermal power at night.

As a result, in the last few years, there has been a surge in startups that leverage CSP’s thermal energy storage as a standalone technology to deliver heat or steam to industrial processes from stored heat. These have been spinoffs from concentrated solar research or CSP development, such as Malta (boosted by the Bill Gates BEV) and Heatrix, a DLR spin-off that just won the SET awards, or Rondo, which is a spin-off from GlassPoint, which was itself a direct heat/steam start-up.

The Norwegian thermal storage startup, Kyoto Group recently won the COP28 Energy Transition Changemakers award for Heatcube.

How the Heatcube started

Kyoto Group began life with a solution to replace wood-fired heat used in the tea industry in rural Africa, for which it won the 2009 Financial Times Climate Change Challenge competition.

“The idea was to try to bring cheap heat to Africa,” explained Kyotogroup CCO Tim de Haas. “The challenge was that farmers were using a good portion of their land to cultivate forests to grow enough wood to burn for drying the tea tree leaves. The idea was to make a simple solution that doesn’t cost much: a mini CSP plant.”

But in trying and testing various ways of implementing CSP for drying the leaves, the industrial investors onboard at the time recognized that the real value is with the storage aspect, for industrial heat. As a result, by 2020, Kyoto Group had redefined the purpose and focused entirely on thermal energy storage.

“And from then on, it was a journey to identify the best way of conceptualizing each of the key aspects to keep it as pure as possible to make it fit for different purposes,” said de Haas.

Now, as Kyotogroup, with the same technical lead but with a new CEO and investor partners, the firm has innovated a unique modular form of standalone thermal energy storage.

Since 2022, Kyoto engineers have closely collaborated with Silvia Trevisan, Head of Thermal Energy Storage Research at KTH, the Royal Technology Institute in Sweden, and Rafael Guédez, Senior Researcher and Lecturer at KTH, as part of a ‘scale-up + science’ initiative within Kyoto. This collaboration has included project funding for her post-doc RIHOND (Renewable Industrial Heat on Demand), and project partnerships like the recently announced SCO2OP-TES project, a Horizon Europe project funded by CINEA – European Climate, Infrastructure, and Environment Executive Agency. The project aims to develop a first-of-its-kind Thermally Integrated Pumped Thermal Energy Storage (TI-PTES) system based on sCO2 machines.

How it works

The Heatcube uses a series of modular tanks to store energy in molten salts that go from cold to hot between 170°C and 500°C. Instead of the two molten salts used in CSP, the tanks are filled with a combination of three salts.

“The benefit of these three salts is we have a lower solidification level,” explained de Haas.

“Compared to the salts from CSP. that solidify at about 290°C, our salts won’t solidify until they get down to 131°C. So we can deliver at a much lower temperature than the salts in CSP, which means we can use different materials for the tanks, so our steel is less expensive, and we reach a broader range of customers.”

This temperature range is helpful in a wide range of industrial processes, and the delivery profile can be customized to fit the customer’s specific requirements the heat output form and the different pressure requirements.

Electricity from surplus solar or wind (or the grid itself) is used to heat the molten salts in the tanks using resistance heating, like the way the element in an electric kettle boils water.

The Heatcube consists of three different elements. First, the charging unit transfers electricity as heat into the hot molten salt. The second element is the storage and circulation system itself, the tanks filled with molten salt. And the third element is the steam generator heat exchanger that converts the stored heat to meet that industry’s need. There are three different options available depending on which type of thermal exchanger is needed; whether to deliver the heat as steam, hot air, or thermal oils.

“So the Heatcube is based on proven technology,” de Haas noted. “We are utilizing the experience and knowledge from the CSP world but making it modular so it is adaptable. And one of the key features is that we can charge and discharge simultaneously. So, while we are discharging the heat, we can utilize any electricity from any off-grid or available low-cost grid connection. At the same time, we continue to discharge and deliver steam to industrial sites.

Like batteries, thermal storage leverages the increase of solar PV on the grid, which has driven electricity prices down during the day and up at night to buy while prices are low and to deliver the heat from storage when prices are higher.

Long duration, long lived, like hydro

Storing energy thermally is cheaper than batteries, runs longer hours, and lasts through many more years of daily cycling. In this way, thermal storage is more like an older renewable energy storage technology in cost and longevity—pumped hydro.

The irony for Heatcube is that this low-cost, long-duration thermal storage makes the home country less attractive as a market for thermal energy storage, as Norway already has plenty of low-cost, long-term energy storage in hydro.

“So in Norway, we only produce as much electricity as we need, and the result is that price differences throughout the day are less in Norway than in Central Europe,” he said.

“The main markets for us actually are in Germany and Spain. Germany has the largest requirements for industrial heat in Europe. And today, the industry uses a lot of gas to produce that heat. So our main focus is to replace industrial gas boilers, helping industry reach targets for reducing CO2 emissions by replacing gas boilers with renewable energy delivered on a 24-hour basis.”