CSP hybridized with MED desalination payback times

A team of Australian researchers at the University of New South Wales (UNSW) has combined three tools to assess the economic viability of a hybrid CSP and desalination plant applicable for any region worldwide.

“The interesting thing is you can modify this by yourself,” lead author Yingfei Huang explained. “You can put any new region in. Each has different background information. You can decide the weight factors and calculate the scores yourself to find the local payback period.”

Ensuring an economically feasible payback period for desalination hybridized with a CSP plant is complex due to the interaction between multiple factors that must be weighed against each other.

Solar resources must be considered, but so must ocean protection areas, seawater salinity, coastal elevation, the degree of water scarcity, land use restrictions, wind speed, and population proximity to potential desalination sites, which can be no more than 250 km from the coast to be economically viable.

The three tools the team combines are the Geographical information system (GIS), Multi-Criteria Decision-Making (MCDM), and their techno-economic model to determine payback time.

GIS, the first tool, already assesses site suitability for CSP projects. However, many additional variables come into play to find the best site hybridized with a desalination project.

So, the second (MCDM) allows the input of all the variables in site selection for desalination, including AHP, which helps decision-makers decide how much weight to attach to each factor’s score.

The third tool was their two-section techno-economic model focused on the payback period considering DNI, ambient temperature, wind speed, distance to seawater, elevation, seawater salinity, and seawater temperature. The first section of this simulates the CSP plant using the System Advisor Model (SAM), while the second incorporates the CSP-MED model in MATLAB code. Each subsystem, including the PTC, the Regenerative Feedwater Heating Rankine Cycle, and the cascaded MED system, is defined, and their interactions are modeled to evaluate system performance.

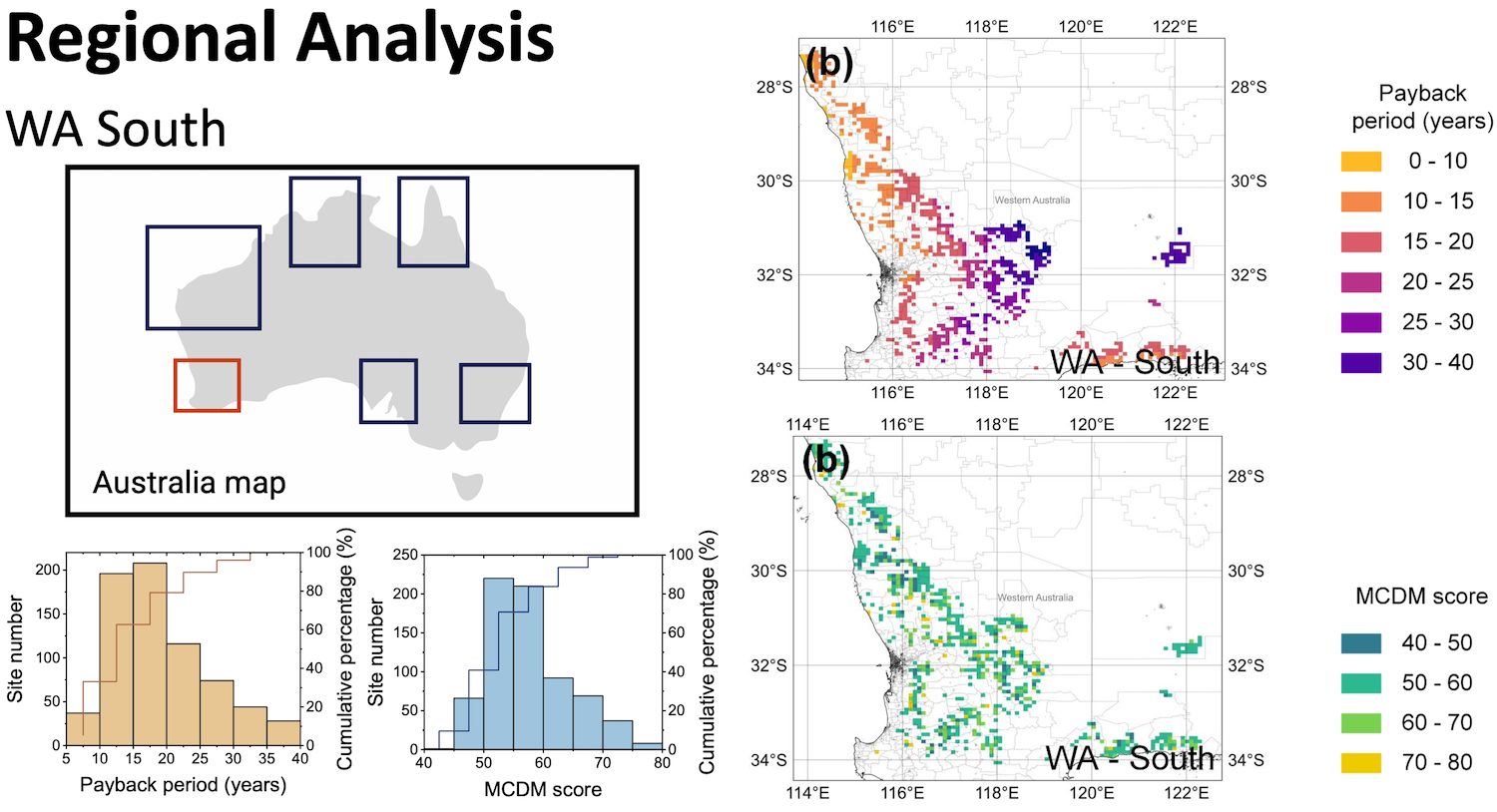

At the SolarPACES Conference held in Sydney this year, Huang demonstrated the results using Australia as a test case to showcase how these tools could work together anywhere in the world.

“For this case study in Australia, the resolution is 10 kilometers, but we can change the resolution,” she said. “For the global tool, we use 50 kilometers, but if you want to go deep, you can set the resolution to one kilometer. It depends on how much CPU you want to use.”

Western Australia is the overall winner

Australia’s eastern coast has the vast majority of the country’s 20 million population and would seem to be the obvious choice for this CSP desalination hybrid.

“But all down the east coast of Australia, the DNI value is not that high,” Huang pointed out. “And then we also have ocean-protected areas in Queensland on the north with the Great Barrier Reef, so we cannot get in there, use any old seawater in that area. And the Blue Mountains are there when we go down around Sydney and New South Wales. The elevation in that area is pretty high.”

Huang noted that the percentage of land slope within 250 km of the coast is one major factor that reduces economic viability.

“For example, Chile has very good DNI, but the elevation at the coast is very high,” she said. “So if you put a plant there, you need to pump the seawater to the top of the mountain. So, land slope indirectly influences your payback period because you need to consider the cost of pumping and pipelines.”

Payback periods for CSP – MED desalination sites surrounding Perth (in black)

By contrast with the east coast, the team found an abundant 56,000 km2 of suitable low-lying coastal sites in Western Australia, including surrounding Perth (pop. 2 million), Geraldton, and Karratha. Average daily DNI is nearly 7 kWh/m2 in some sites. So, despite the lower population density, Australia’s west coast was the overall winner, with payback periods for some sites of less than ten years.

The runner-up was the Port Augusta area in the south, with DNI averaging over 6 kWh/m2 in just over 25,000 km2 of suitable sites, yielding payback times averaging 14 years.

(Along Australia’s northern coast, despite an excellent solar resource (DNI averages almost 8 kWh/m2), exposure to strong winds and cyclones would make continuous operation difficult there, reducing the efficiency of any desalination plant.)

The team proposed a 50 MW CSP plant, producing electricity in a hybrid setup (which also helps economic viability) with 8 hours of thermal energy storage.

“You need the plant to operate for 18 to 24 hours – but a battery is too expensive,” said Huang.

Why a CSP – MED hybrid for desalination

Multi-Effect Distillation (MED) desalination is a thermal technology using heat, while reverse osmosis (RO) desalination uses electricity.

“But we did some previous research comparing MED and RO for seawater desalination technology. If the salinity is too high, RO faces some problems,” she said. “MED isn’t much impacted by water conditions like seawater temperature and salinity, but these impact RO strongly. The membrane gets blocked by all these kinds of impurities and salts. So you’d have to replace the membrane several times during operation. And if we consider a global scale, if you go to the Middle East and North Africa, the salinity in that area is pretty high, up to 45,000 ppm.”

The other advantage of hybridizing CSP with MED is that the desalination can be 100% solar, according to Dr. Diego-César Alarcón-Padilla who who heads the Solar Desalination Unit at Plataforma Solar de Almería (PSA) and is Operating Agent of Task VI of SolarPACES.

Desalination must run around the clock.

Electric desalination with PV, even when directly connected to a solar farm, tends to be less than 100% renewable because the usual backup for nighttime is the grid, which is cheaper than adding batteries. But in most places, the grid is only partly renewable.

By contrast, CSP plants include cheap thermal energy storage for after dark and naturally generate waste heat in the temperature range used to run MED desalination, so a pairing of the two makes for the perfect hybrid.

“This is precisely why we chose CSP with MED,” said Huang, a chemical engineering PhD candidate whose interest in water security led her to this field of solar research. “The operating temperature for this desalination technology can comfortably range between 60-70°C. This means that elevating the CSP turbine outlet temperature to this specific set point will have minimal impact on the overall system’s efficiency. So basically, we want thermal desalination with the cheap thermal storage of CSP, and we’re also able to reuse the waste heat for the desalination. So we found that CSP with MED yields the best return on investment, the ROI.”

———————————

SolarPACES Presentation: GIS-driven Method for Large-scale Solar Thermal Seawater Desalination Feasibility Assessment: A Case Study in Australia