Thermochemical Oxygen Pumping with Perovskite Reticulated Porous Ceramics for Enhanced Reduction of Ceria in Thermochemical Fuel Production

Abstract:

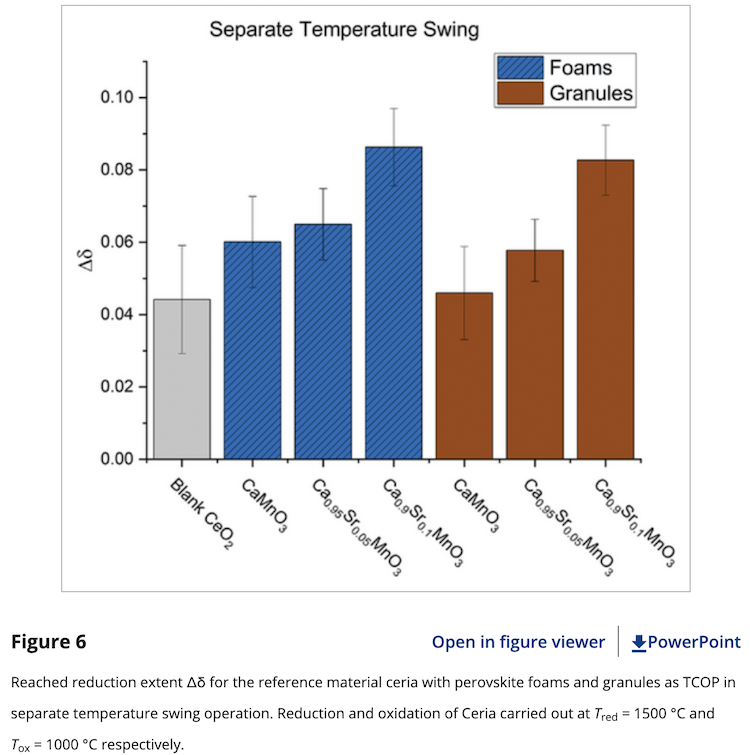

Within this work, reticulated monolithic foams and granules made from CaMnO3 − δ and strontium substituted variations are demonstrated to significantly improve the performance of a water splitting redox oxide when employed as a thermochemical oxygen pumping material. Two different process procedures are tested and foams made from Ca0.9Sr0.1MnO3 − δ with a strontium content of 10% outperform all other specimens in both process configurations. Additionally, the performance of Ca1 − xSrxMnO3 − δ with varying strontium content as a thermochemical oxygen pumping material is studied by means of a newly developed theoretical process model. While the model does not precisely predict the excellent experimental performance of strontium-substitute compositions, it provides valuable insights into the impact of geometry and structure on the specimen’s performance in thermochemical oxygen-pumping processes. This work demonstrates the practical application of monolithic 3D structures made entirely from perovskite material in thermochemical oxygen pumping processes and provides a process model that can serve as basis for material screening and process optimization in future work.

Pein, M., Keller, J., Agrafiotis, C., Eltayeb, A., Klaas, L., Neumann, N., Roeb, M., & Sattler, C. (2024). Thermochemical Oxygen Pumping with Perovskite Reticulated Porous Ceramics for Enhanced Reduction of Ceria in Thermochemical Fuel Production. Advanced Energy Materials, 14(19), 2304454. https://doi.org/10.1002/aenm.202304454