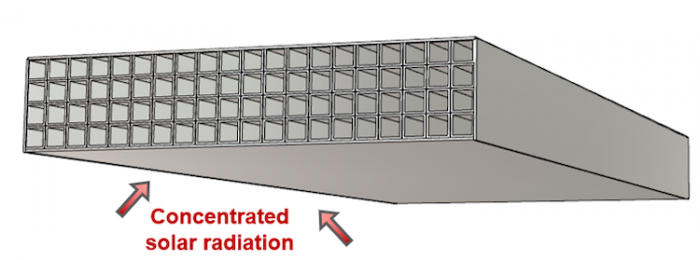

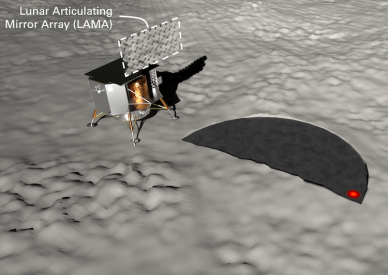

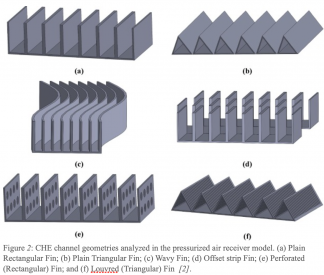

Star receiver compared to cylindrical receiver. IMAGE © Enhancing solar tower competitiveness with star-shaped receivers.

In a comprehensive new study published in Applied Energy, researchers find that a new streamlined version of a star-shaped solar receiver can collect more thermal energy and last significantly longer than today’s cylindrical solar receivers used to collect heat in solar tower CSP.

The new triangular star design could generate up to 75% lower capital costs and 30% lower Levelized Cost of Heat (LCOH), according to the paper Enhancing solar tower competitiveness with star-shaped receivers.

The study by the teams at Politecnico di Milano and Queensland University of Technology fills a gap in the literature by providing the first comprehensive, multi-disciplinary, and plant-scale analysis of star-shaped solar receivers for molten-salt-based solar tower CSP.

Building on earlier star receiver designs

“Past studies already showed the star design’s optical and thermal potential, and showed that double-sided irradiation could extend the receiver tubes’ lifetime” noted lead author Giancarlo Gentile, in a call from Italy about the new paper.

“What was missing was comprehensive analysis; energy performance, optic performance, mechanical durability, heat transfer fluid pressure drop, resistance to the wind load, and economic analysis.”

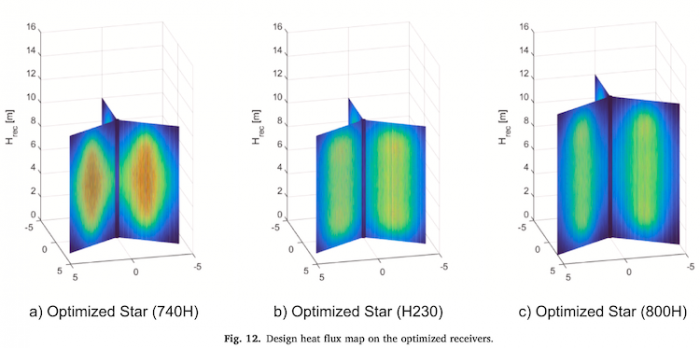

Three star receiver options compared. IMAGE © Enhancing solar tower competitiveness with star-shaped receivers.

“We optimized the height of the receiver, the number of tubes, and the tubes diameter and we compared three different materials for the receiver tubes,” said Gentile.

“By coupling optical performance assessment tools with thermal and mechanical models and economic considerations, we were able to consider all this information together, and to optimize the design of this innovative star-shaped receiver minimizing the Levelized Cost of Heat (LCOH).”

These earlier star-shaped receiver studies, such as the five-pointed star by Cathy Frantz and colleagues at DLR, projected LCOE reductions of around 11% mainly due to smaller receiver size and a 1% boost in optical efficiency.

Three pointed star instead of five

The new comprehensive analysis confirms and extends these findings, showing that with three points instead of five, and full system optimization including modifying the solar field, as described in their paper, the potential savings in CAPEX (75%) and LCOH (30%) could be even better.

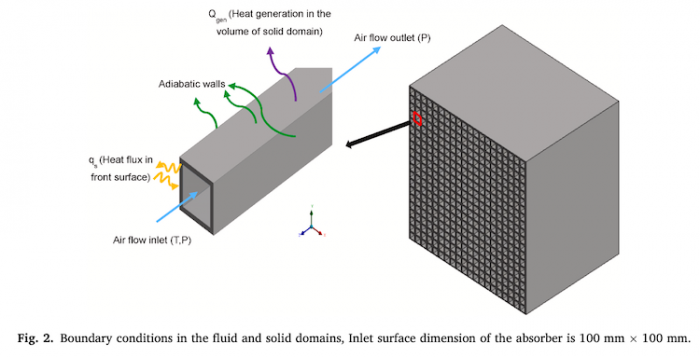

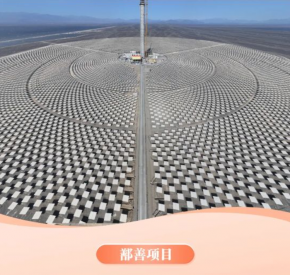

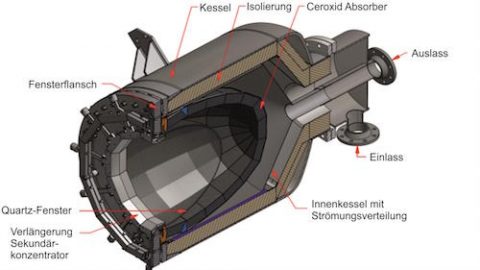

Most of today’s commercial solar tower receivers running a molten salt mix to transfer heat are cylindrical. Hundreds of absorber tubes going up and down in a serpentine fashion around the cylinder shape form a single outer surface exposed to the solar flux. (This cylinder atop a tower is heated by sunlight reflected from a solar field comprising thousands of heliostats – mirrors).

However, because only the outside of each tube gets directly irradiated, this creates steep temperature gradients, greatly limiting how much heat can safely be absorbed before the tubes risk thermal shock.

Star shaped receiver advantages

Instead, in star-shaped receivers, both sides of each tube in the star’s points get exposed to sunlight. The star-shaped design traps stray light and reduces reflection losses by allowing both sides of the tubes to absorb sunlight.

The thermal gradients that typically drive creep and fatigue damage are reduced by illuminating both sides of each tube. This dual-surface exposure leads to more uniform heating, significantly lowering thermal stress. This is why star-shaped receivers have been investigated.

Star-shaped receivers not only halve the number of tubes needed for the same heat input but also equalize temperatures around each tube, allowing for higher flux densities and reduced thermal stresses. The receiver can now be smaller and cheaper, with fewer materials and simpler construction.

The team performed a detailed creep-fatigue analysis—accounting for both daily thermal cycling and long-term high-temperature operation—which shows that this star geometry can enable lifespans far exceeding the standard 30-year design target.

Less thermal stress opens up lower cost material options

The researchers also evaluated three materials for a three-armed star shape, as cheaper tube materials were now viable with the reduction in thermal stress. The study is the first to systematically compare three tube material choices for star receivers: Incoloy 800H, Inconel 740H, and Haynes 230.

Their results showed that the lower-cost 800H alloy can be used without sacrificing durability, reducing material costs significantly compared to high-performance, high-price options like Haynes 230.

The new star geometry further improves optical efficiency. Being able to handle more intense solar irradiance means more compact receiver designs with up to 50% fewer tubes, cutting receiver manufacturing and maintenance costs.

Now make the solar field ‘match’

They also wanted to know: How much cheaper and better is a star shaped receiver when the solar field is also customized to best aim at the new configuration?

“Previously, only a few studies were published, and they only focused on specific aspects,” said Gentile.

“They did not propose tools to analyze this technology comprehensively, or show a techno-economic comparison between this technology and the state-of-the-art cylindrical configuration. We proposed a methodology to optimize the design of this innovative concept and we showed that, for a solar field similar to Spain’s Gemasolar plant, the optimized three-arm star-shaped receiver would result in a 10% reduction in LCOH compared to a cylindrical receiver using the same solar field, similar to the DLR results.”

He added that if the optimized star-shaped receiver is coupled with a solar field specifically designed for the star geometry, the Levelized Cost of Heat of Solar Tower plants can be reduced by up to 30%. That is a significant reduction.

Published at Applied Energy – Enhancing solar tower competitiveness with star-shaped receivers