Following their review, published at Astra Astronautica, covering all previous research using concentrated solar energy to generate heat for melting lunar regolith, co-authors Stéphane Abanades, Sylvain Rodat and PhD student, Jack Robinot, propose that the most promising technology to extract oxygen using concentrated solar could be vacuum pyrolysis.They have just performed their first test.

“We carried out experimental work with the support of CNES and the European Space Agency and demonstrated the direct use of concentrated solar energy to achieve vacuum pyrolysis of lunar regolith simulant,” said Abanades.

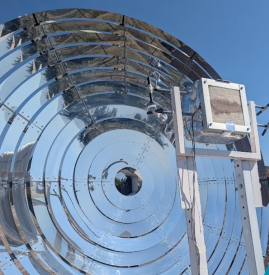

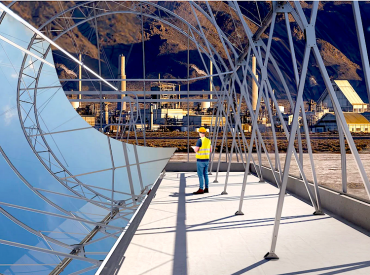

“Using unique world-class CNRS research infrastructure located at Odeillo Solar Furnace (France), consisting of solar concentrating facilities capable of reaching temperatures up to 3000°C, we successfully quantified oxygen yields and demonstrated the simultaneous recovery of metallic by-products without the need of any additional reagents, thus reducing reliance on Earth-based resupply.”

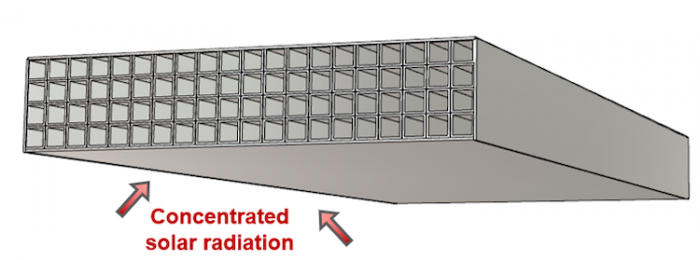

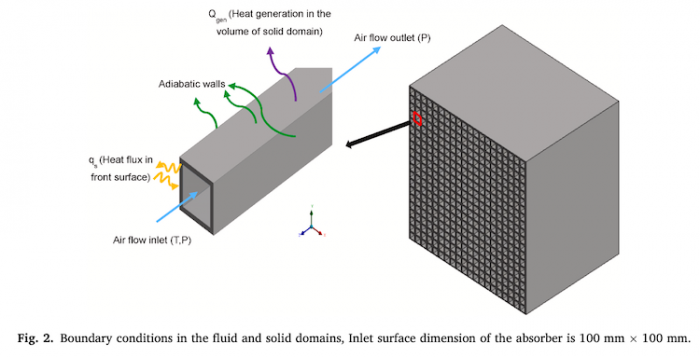

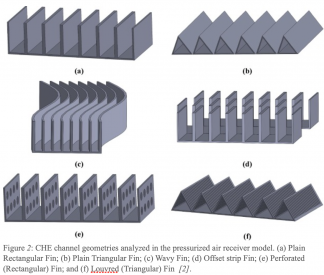

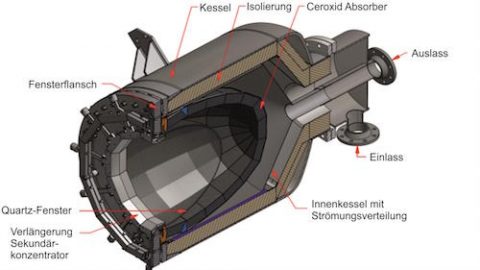

The solar vacuum regolith pyrolysis was conducted in a dedicated solar reactor, designed at the PROMES-CNRS laboratory for experiments involving concentrated solar energy under controlled atmospheres.

The technique was based on their previous experience gained on metal oxide reduction applied to thermochemical fuel production cycles, and it was adapted for regolith pyrolysis. The experimental system aimed to replicate the harsh conditions of temperature combined with low pressure found on the Moon.

The concentrated solar advantage on the Moon

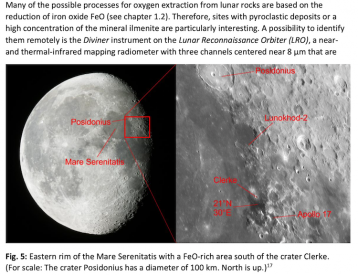

Most processes for extracting oxygen from lunar soil require heat. (Oxygen makes up about 42% of lunar regolith, most of it in the form of oxides of silicon, aluminum, calcium and iron, plus magnesium, titanium, sodium, potassium oxides, and others.)

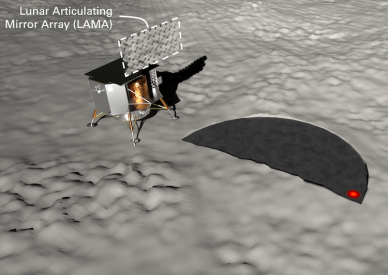

The most cost-effective way to bring heat to the moon is to utilize concentrated solar energy, because it involves only mirrors or heliostats that reflect and concentrate sunlight. Lunar sunlight is unobstructed by atmospheric attenuation or clouds and runs “around the clock” for 14 equivalent Earth days.

Concentrated solar researchers have investigated various strategies, ranging from aiming the concentrated sunlight directly at the regolith to melt landing pads, to aiming it at a solar receiver submerged in ice to melt it, and performing the solar-driven oxygen extraction chemistry in a fluidized bed receiver.

Abanades pointed out that for oxygen extraction using solar, vacuum pyrolysis in the Moon’s vacuum conditions is thermodynamically favored by both high temperatures and low pressures.

“This process leverages the Moon’s environment, its ultra-high vacuum, and abundant solar energy resource on the lunar surface, turning these harsh environmental constraints into enablers,” he noted.

“Unlike other investigated methods, solar vacuum pyrolysis requires no consumables or reductants, it only uses abundant regolith and solar resources, and operates under conditions naturally available on the lunar surface, enhancing its feasibility for large-scale ISRU (in-situ resource utilization) applications.”

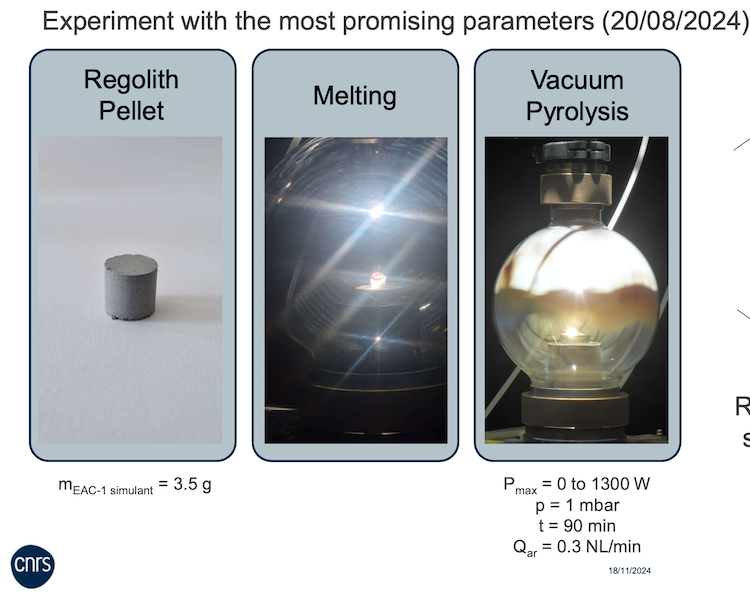

Their vacuum pyrolysis test setup

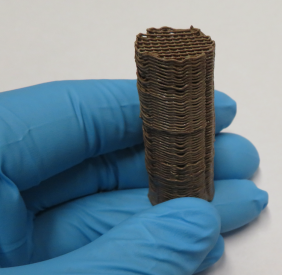

The vacuum reaction chamber they tested comprised a glass sphere with two ports. The regolith sample is placed on a water-cooled copper holder as a pressed pellet. They created lunar vacuum conditions in the chamber using a pump. They heated the sample with a solar dish concentrator, combined with a sun-tracking heliostat (essentially, two mirrors that reflect and then concentrate sunlight) to generate heat above 1200°C to melt the regolith.

No reducing agent is needed; just high temperature and very low pressure.

The heated molten regolith then emitted gases, including oxygen, which is collected while the vaporized metal residue is condensed and filtered off. The gases were analyzed by mass spectroscopy and dedicated oxygen analyzer to determine the oxygen extraction yield.

“Using concentrated solar energy with a maximum flux of 4.8 MW/m² under vacuum conditions at one mbar, we extracted 20 mg of oxygen from a pellet of 3.5 g, corresponding to a mass yield of 0.6%. This represents 1.4% of the total oxygen available in the regolith simulant, recovered as gaseous oxygen. In more recent solar experiments, performance was improved with the production of 35 mg of oxygen from a 3.38 g regolith pellet. This corresponds to an oxygen extraction mass yield of 1.04% of the total sample, and 2.47 % of the total simulant oxygen mass content was thus recovered,” Abanades explained.

“What we did was to demonstrate the process by quantifying the yield that can be obtained with the current setup that we have developed in Odeillo, as no experimental study yet quantified oxygen production to date. These values provide the first quantification of oxygen production from regolith solar pyrolysis” added Robinot, in a call from France.

“We wanted to see what the limitations of the process are and what we can do in the next step to improve the oxygen yield. We need a turbo molecular pump to reach a lower pressure. Currently, we are working at approximately between one and 10 millibars, and we would like to reduce the pressure inside the reactor to be closer to what would be achieved on the Moon.”

More work needed to advance this technology

The team also demonstrated the simultaneous recovery of metallic products by thermal reduction of regolith, which could be usefull as construction materials on the Moon. The researchers will also analyze these collected solid metallic products from minerals thermal reduction to assess their potential usefullness on the Moon. And more research is needed to characterize the reduced metallic species and optimize their recovery and separation.

As an early-stage investigation of vacuum pyrolysis using concentrated solar, these initial results showed that even with a lower vacuum than lunar conditions, they successfully extracted oxygen from the regolith. However, to get an accurate idea of how it would actually perform on the Moon, they need a setup that can work with secondary vacuum, so the pressure inside the vacuum chamber would better replicate the actual lunar vacuum. These initial tests confirm the feasibility of vacuum pyrolysis of lunar regolith as a promising technology for extracting lunar oxygen with concentrated solar energy

Given the high cost to transport each kilogram from Earth to the Moon, the more that lunar resources can supply what is needed there, the more feasible lunar engineering becomes. Vacuum pyrolysis requires only the solar concentrating mirrors, a cavity-receiver for the reaction, and a separate container for the oxygen storage. No reactants and consumables need to be brought up from Earth. So, it meets the necessity to minimize transport costs.

PSA advances a solar reactor to extract oxygen from lunar ilmenite

Startup concentrates solar to melt NASA’s lunar landing pads