A new paper from researchers at PROMES-CNRS in France presents a control strategy to reliably deliver a precise thermal power from concentrated solar to meet industrial heat requirements.

The objective was to design a proof-of-concept algorithm for operating a concentrated solar plant, but one intended primarily to deliver heat, and deliver it from thermal energy storage tanks rather than from each moment’s sunlight, as in a typical CSP power plant.

“There are lots of studies on the control of solar plants, but most of them are on CSP plants, with only power production objectives. So you can find lots of references trying to, for example, use an optimization algorithm to maximize the profit you can make with such a plant. But this is not our objective. Our objective was to satisfy a heat demand from industry.” said lead author Eliott Girard in a call from France.

To do this, the algorithm would control the flow rate of the hot storage liquid to deliver a required thermal power throughout the day.

“We are focusing on operational constraints, such as what happens when you have a larger DNI drop, on a smaller time scale, to determine the best mass flow rate in the plant over a short time horizon,” Girard explained. “This is what’s new about our study.”

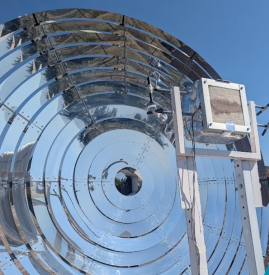

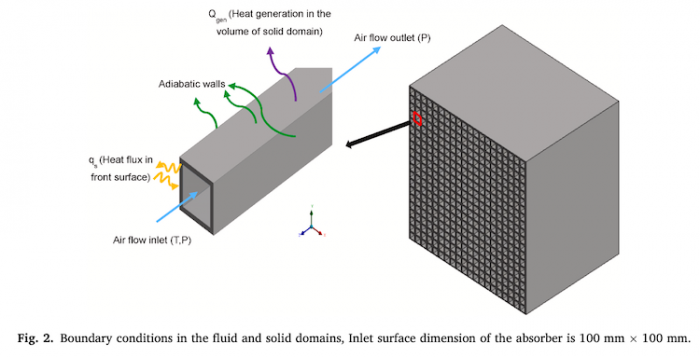

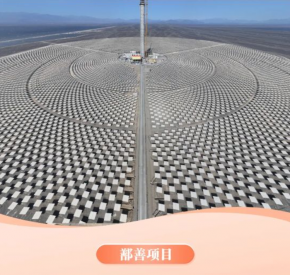

The setup would comprise a solar field of parabolic trough collectors, delivering oil heated by focused sunlight to a single thermocline thermal energy storage tank, so that heat would primarily be drawn from the storage tank.

A thermocline storage with particles in oil

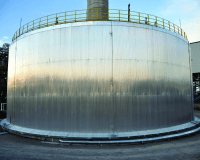

In thermocline storage, both the heated and cooled heat-transfer fluid is stored in a single tank. This creates a region of a mixed temperature (a ‘thermocline’) in the middle.

When this thermocline region can be minimized, it reduces costs to store both temperatures in a single tank. The solar-heated oil enters at the top, and once the heat is extracted by a heat exchanger in the middle, the now-cooler liquid sinks to the bottom. This cooler liquid is then routed back to the parabolic trough collector field for reheating by focused sunlight.

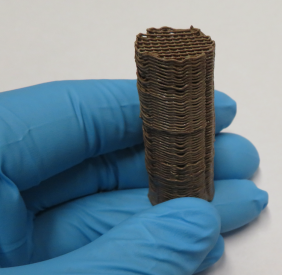

The study assumed that the liquid would be the thermal oil, the standard in commercial trough-type CSP plants. Small pebble-like particles inside a basket in the oil would store additional heat.

“We created this algorithm on the assumption that we would have particles in the oil,” Girard explained.

“The advantage of this is that the solid particles increase their storage capacity. And also, solid particles enhance stratification at the thermocline. So you can have a clear thermocline zone, a clear separation between hot and cold. That’s also why this tank has that high capacity, because there are lots of particles which also store some energy.”

A practical solution for many industrial heat uses

The plant would use the control system to ensure the correct amount of heat is delivered by adjusting the flow rate of the heat-transfer fluid through the system. It is possible to increase or slow the flow rate by adjusting the pumps.

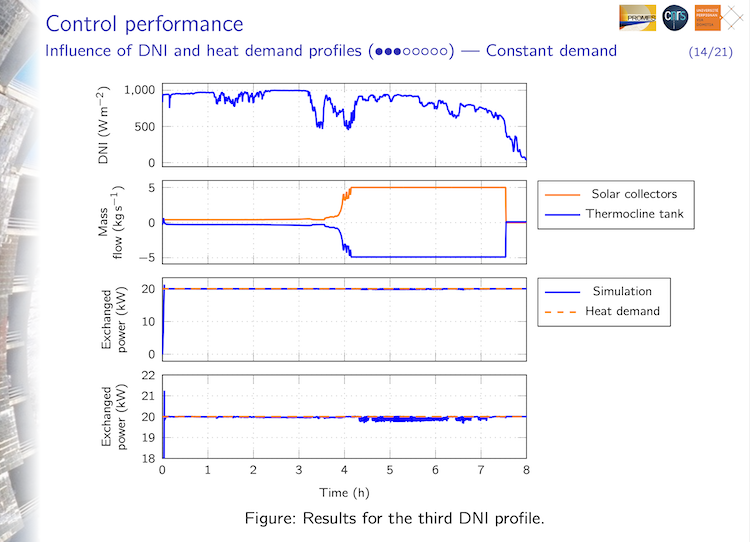

The team tested the setup under three scenarios: steady heat needs, on-and-off heat needs, and slowly changing heat needs (similar to what’s needed in paper processing, for example).

The effectiveness of the control algorithm was judged based on two factors:

How much the delivered heat deviated from the target and how much the system overshoots the target when responding to changes.

The team tested three heat-demand scenarios, all simulated under clear-sky, overcast and mixed conditions.

Constant demand: Steady 30 kW thermal power throughout.

Batch demand: Alternates between one hour at 60 kW and one hour with no heat required.

Realistic demand: Gradual changes typical of a paper treatment process during the day.

In all cases, the control system did a good job keeping to the target, with only minor differences from what was required and not much “overshoot” (where the system briefly gives too much heat). The system handled both slow and rapid changes in heat demand and incident solar energy reliably, suggesting it would perform well in other real-world situations.

High ratio of storage to solar field

When concentrated solar power is used primarily to supply a storage system, it should have relatively more storage capacity than the solar field, but determining how much is a work in progress.

Because it would primarily draw on stored solar thermal energy rather than on the sunlight incident on the solar collectors themselves, the prototype plant simulated in the study would have a higher solar ratio than conventional CSP plants. A small 150 kW solar field of parabolic trough collectors would be paired with 1,100 kW of thermal storage, a much higher ratio than in a CSP plant generating power.

“But this might be too extreme a ratio,” Girard considered. “I think the storage tank is actually too oversized in relation to the collectors.”

Next, Girard will be revisiting the effect of the storage tank size relative to the solar field.

The case study is based on a real plant at the PROMES laboratory.

But he emphasized that what is really needed at this point is physical validation:

“There are very few studies concerning the control of CST plants that are based on a physical plant; it’s mostly simulation. Physical validation of the control strategies is lacking. They almost always remain as only validated by simulations, but they need to really implement control strategies,” he said.

Read the Paper; Control of a concentrated solar plant for heat production under various thermal demand and the SolarPACES 2025 Conference Presentation: Model-Based Predictive Control of a Concentrated Solar Plant for Heat Production