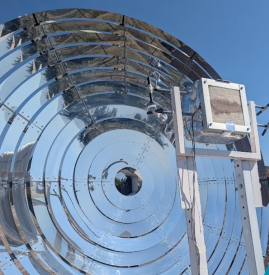

Solar researchers at Fraunhofer Chile have designed, built, and tested a complete solar collector and crucible system for melting and recycling aluminum, heated by Annular Fresnel solar collectors. In Annular Fresnel, each mirror is flat, like a Fresnel mirror, but arranged in a circle, enabling the very high concentration possible with Dish solar concentrators.

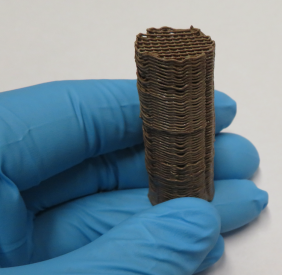

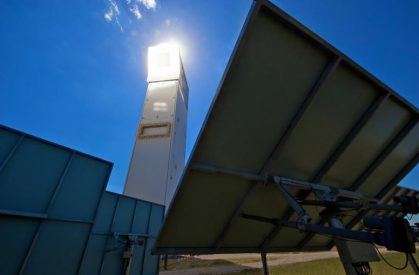

The Annular Fresnel concentrators they had manufactured locally are sliced from silver-coated acrylic sheets. The team built a full system, including a complete crucible furnace and a handling system, which has been operated through multiple aluminum melt/pour cycles under real DNI conditions in Chile for this application‑specific innovation and engineering demonstrator.

They showed that their setup, designed explicitly for aluminum recycling, will operate at the required high temperature at low cost and on a practical scale. As they revealed in a well-received presentation, Fresnel Solar Furnace for Aluminum Melting, and paper at the 2025 SolarPACES Conference in Spain, the team has successfully cast branded ingots during tests.

“We bypassed the standard laboratory phase and moved directly to testing in a relevant environment,” said lead author Pablo Castillo, in a call from Chile.

“It involved significant trial and error—specifically, determining exactly when the aluminum was molten by relying solely on the furnace’s temperature sensors, without visual confirmation.”

Local manufacturing limitations led to their choice of Annular Fresnel concentrators

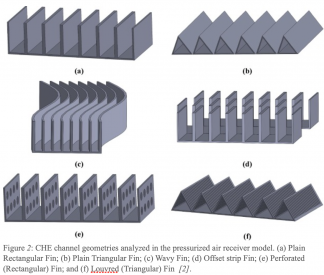

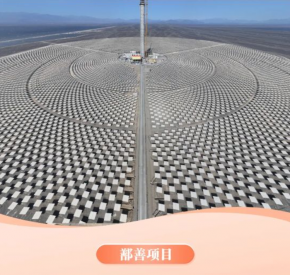

Annular Fresnel concentrators are a cross between linear Fresnel reflectors – long lines of flat mirrors – and the highly concentrating solar Dish, in which each little mirror is curved. Annular Fresnel concentrators have the high-concentration advantage of Dish collectors but are simpler to manufacture because they consist of flat mirrors arranged in concentric reflecting rings. In this case, the mirror surface was achieved with silver-plated acrylic plastic.

“Our challenge was achieving this level of concentration using Chile’s local manufacturing capabilities,” Castillo explained.

“We hit a wall realizing we couldn’t manufacture a three-meter parabolic dish locally. Instead, we adopted a simpler design based on the linear Fresnel concept: 13 concentric rings on a single plane with varying slopes. We were pleasantly surprised to find that, even with local limitations, we could successfully achieve these complex geometries.”

Because Fresnel systems are typically linear, they need only single-axis tracking. However, by combining the low-cost Fresnel flat mirrors into a circular Dish-like configuration, the tracking system requirement also changes. The team innovated a slewing drive system for dual-axis tracking for their concentrator to accommodate the change.

Why Chilean aluminum recycling

With its world-leading DNI, Chile has vast regions where this simple solar technology for aluminum melting can recycle aluminum and other metals with similar melting points. And increasingly, Chilean policy requires metal recycling.

Currently, aluminum is exported to Brazil for recycling. The Fraunhofer team believes that, by building a deployable system for large cities in Northern Chile, where there is abundant solar resource, they can recycle aluminum using solar energy domestically and then sell it to companies looking for aluminum with a zero-carbon footprint.

“We have seen significant interest from major multinationals in the food and beverage sector who are pursuing circular economy goals for their packaging,” said Castillo.

“Our industrial partner, who currently exports scrap aluminum, noted a shifting international demand toward ‘green aluminum’ produced with near-zero carbon emissions. We are working together to develop this technology for coastal cities with major ports, as well as more populated areas in the Central Valley of Chile.”

What the experiment proved

The team proved that this simple-to-manufacture annular mirror geometry, combined with their practical, field‑tested aluminum recycling furnace and control system, is a feasible, low-cost route to industrial aluminum recycling.

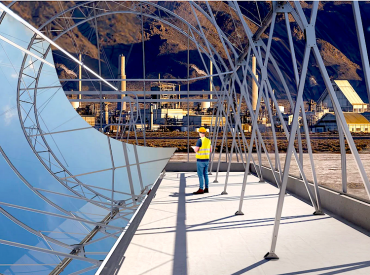

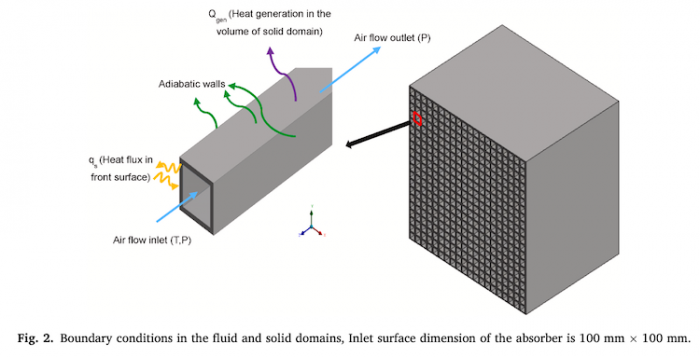

Designed to maintain the crucible strictly within the optimal processing range of 520–640°C for repeated aluminum pours, their system utilizes a unique ring‑mirror field on a compact slewing drive. With full two‑axis tracking and custom controls, the setup successfully managed the melt-pour cycles using relatively modest, locally manufactured equipment compared to the giant solar furnaces typically used for research, such as those at Odeillo.

In 21 outdoor trials conducted between November 2024 and May 2025, the team established a reliable industrial workflow. On a representative high-performance day (April 8, 2025), the system achieved a maximum daily melt of 1.71 kg under a median DNI of 902 W/m², successfully executing multiple pour-and-recharge cycles. The results have been validated via a six-node thermodynamic model, confirming the system’s potential for scaling.

The system integrates custom electronics, software, and a sun-tracking mechanism for azimuth and elevation, installed at Parque Caren in Santiago, Chile (33.4351°S, 70.8457°W). Iterative prototyping optimized optical and thermodynamic performance, with the furnace heating a crucible to melt aluminum and pour it into ingot molds.

Next steps

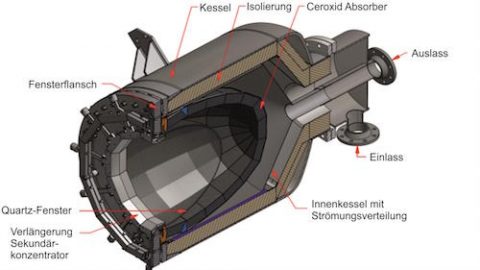

To initially test the concept, it was most straightforward to position the furnace at a focal point above the dish. But in production, for practical reasons, the melting pour would need to be on the ground.

“Manipulating a furnace at 800°C and pouring molten liquid three meters above the ground poses significant safety risks,” he said.

To avoid this high-temperature operation at the natural sky-high focal point, they would add a secondary beam-down reflector, so that the furnace and the molten pour can be stable at ground level.

“While a beam-down reflector might incur slight optical energy loss, we gain stability and reduce exposure to wind and dust. So we believe we can achieve a higher output,” Castillo pointed out.

“We have already developed a ‘2.0’ design where the furnace remains stationary at ground level. Having proven the technology is feasible, our next steps are to refine the design, lower costs, and increase output.”

“Solar energy that can be poured in the fuel tank”: the Aldo Steinfeld Weltwoche interview

Solar furnace to melt steel at 2000°C for Swiss recycler Panatère

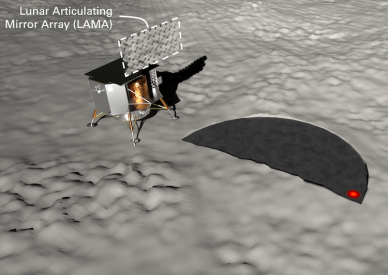

Startup concentrates solar to melt NASA’s lunar landing pads

Why Lunar Engineering is an Exciting R&D Field for the “Hot Solar”