The greenhouses that contain GlassPoint’s 1 GW Miraah solar EOR during construction at the Amal oil field in Oman

Unlike other CSP developers who leverage the heat of the sun as the “fuel” for a power block that then generates electricity to the grid; GlassPoint’s enclosed troughs are simply employed in the direct production of steam, focusing on what the company sees as an ignored market for heat.

“We founded the company to not do electricity,” explained Chief Technology Officer and co-founder, Pete von Behrens, the holder of numerous patents. “Almost everybody else has been focused on the electricity market which competes with very low cost photovoltaics. If you make heat instead, you eliminate the need for a power block and open yourself up to a major untapped market. The demand for heat is much bigger than the solar utility market.”

“We had to take our technology and optimize it for a number of challenges. We first solved the problem of how to make cheap heat, which is the big problem. Then we had to uniquely solve how to keep it clean in super dusty high wind environments.”

Hence; the greenhouses.

How GlassPoint evolved

Even after deciding nine years ago to focus just on producing heat rather than on electricity generation, it took von Behrens and co-founder Rod MacGregor some time to find the perfect application for their technology. While industrial processing uses a lot of heat for steam, or to dry things out, or to heat ovens or kilns, they found that each application has its own peculiarity, making it tough to focus on any one industry need that would constitute a large enough market.

“There are many applications for industrial heat but most don’t have the right amount of scale. There are also technical considerations; for example, the temperature may need to be very hot or heat is needed on a continuous 24 hour cycle, so there’s a lot of peculiarities that can drive costs up,” von Behrens explained. “We didn’t necessarily understand that because of the many different heat requirements, finding the right application was pretty tricky even with heat, and it took us a little time to find the right application.”

The challenge was to find a market that required a temperature range they could meet where they could provide heat at a large enough scale, at a lower cost than natural gas, and of course, found in countries with the high DNI – direct normal irradiance – that is ideal for concentrated solar power (CSP).

The Goldilocks Customer

GlassPoint found that perfect market in the world’s sunny high DNI desert regions of the Middle East. The company has fine-tuned its technology to specifically provide steam for EOR – enhanced oil recovery. The steam helps to flush out heavy oil, which is too viscous to pump to the surface using primary oil production methods.

After a “prove it” pilot demonstration at 7 MW thermal, GlassPoint was able to land the world’s largest order for solar thermal. Miraah, a $600 million, 1 GW thermal solar EOR steam producer for Petroleum Development Oman (PDO), the Sultanate’s largest hydrocarbons producer. The pilot tested one greenhouse unit. Because it is modular, each unit will make its own steam.

“The pilot has been a resounding success,” PDO Managing Director Raoul Restucci said in a testimonial on the company’s website. “It has exceeded its nameplate capacity. It’s met all its criteria. Above all, it’s shown minimal maintenance requirements, very high reliability, and an outstanding uptime in excess of 98% no matter what the weather over the past two and a half years.”

With its massive energy demand and deep pockets, the oil industry turned out to be the Goldilocks customer.

“It turned out to be significantly bigger and better than we had expected. The oil and gas industry is one of the largest energy consumers in the world,” said von Behrens. “Aside from EOR, refining is also very energy-intensive; a lot of thermal energy, usually in the form of steam, is needed to turn crude oil into the fuel that can be burned in your car. Different applications need different temperatures, but it’s all pretty well in our sweet spot.”

Oil is found in deserts, where there is plentiful sun and the conditions are idea for solar thermal. The oil industry needs steam in the temperature range of GlassPoint’s “sweet spot.” It can use balance-sheet funding to shepherd innovative technology across “the valley of death” into full-scale operation – and to top it all off, in much of the Middle East, the natural gas it traditionally uses for EOR is expensive or scarce.

Fossil Fuel Subsidies Indirectly Boosted Solar

Like many Gulf nations, Oman has a growing gas shortage. PDO estimated that with solar replacing natural gas, the company will save 5.6 trillion Btus of natural gas each year.

It might seem counterintuitive that natural gas is scarce or expensive in oil fields. As with other oil-rich regions, natural gas co-occurs in many Gulf oil fields. But perversely there is a disincentive to invest in extracting it, because regional governments have heavily subsidized consumer use of natural gas to ensure domestic tranquility.

Consequently, local natural gas prices are so low that there is little incentive for industry to invest in the infrastructure to extract it. Governments buy cheaper gas on the world market, and oil fields flare it off.

So, while the Gulf is famous for its oil industry, its natural gas industry barely exists. Oman’s neighbour, Qatar has natural gas, but can get a better price on the international market.

So, ironically, in the Gulf, fossil fuel subsidies have – in a roundabout way – made solar a cheaper option.

2008: Pete von Behrens ponders GlassPoint’s initial project; a 300 kW thermal project at Berry Petroleum in California’s oil-rich Kern County.

A Bonus in Enclosing the Parabolic Troughs

To protect from the dusty environment of an oil field the company invented enclosed trough technology. For the enclosure, GlassPoint bought readily available commercial greenhouses used in agriculture – with standard off-the-shelf cleaning robots. This decision had many benefits.

Normally parabolic troughs have to be engineered to withstand wind. But because GlassPoint’s parabolic mirrors are inside the glasshouses, not exposed to wind, they can be much lighter weight than usual, which reduces costs.

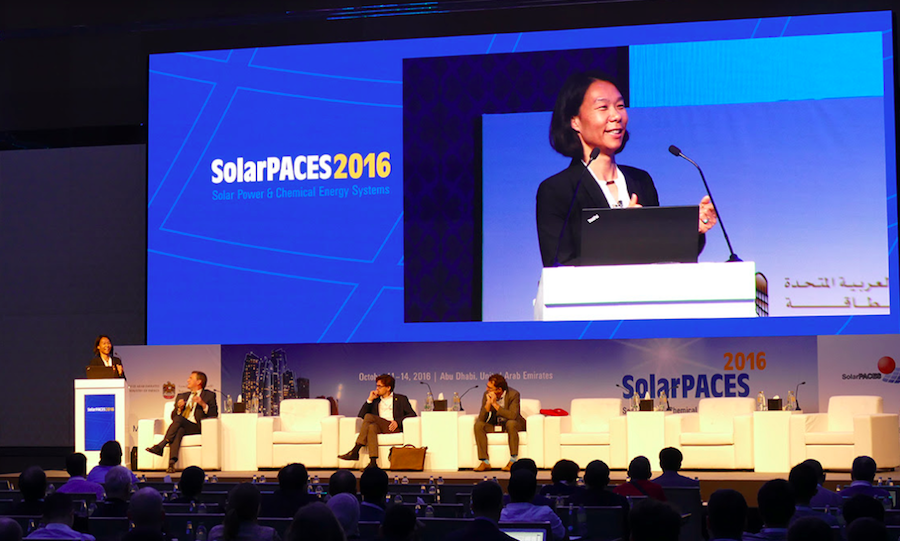

“By eliminating the wind load, GlassPoint is able to use ultra-lightweight, thin reflectors, which are suspended from the roof of the greenhouse,” Dr. Chiaki Treynor, Vice President of Technology at GlassPoint told attendees at the 2016 SolarPACES award ceremony in Abu Dhabi.

“Compared to older solar thermal designs with exposed reflectors, we use a fraction of the raw materials throughout the entire system,” she explained.

GlassPoint Solar won the 2016 SolarPACES Technical Innovation Award for its innovative enclosed trough technology generating steam.

“This has a cascading effect on cost—from reduced shipping costs, installation costs, to using smaller, off-the-shelf motors and drive systems used to track the sun. Since our reflectors are low-cost, we pack them much closer together to achieve the highest ground efficiency of any solar thermal system. This is particularly important for steam generation on oilfields, where siting is limited by active wells, roads and transmission lines.”

Images: GlassPoint