Abstract:

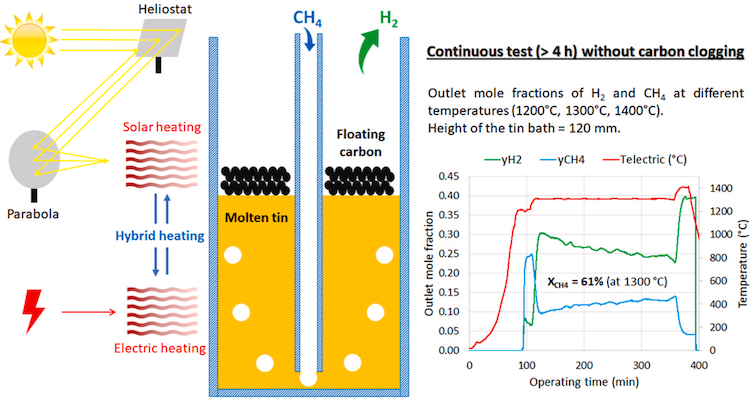

Methane pyrolysis in liquid metals is a worth-developing process for CO2-free hydrogen production. This study investigates methane pyrolysis in molten tin and highlights the impact of several parameters on methane conversion (XCH4) in a novel hybrid solar/electric bubbling reactor. Temperature (1200–1300 °C), total inlet gas flow rate (Q0 = 0.25–0.5 NL/min), melt height (Him = 60-120-235 mm) and hybridization are addressed. Increasing the temperature from 1200 °C to 1300 °C (Q0 = 0.25 NL/min and Him = 120 mm) improves XCH4 (32% vs. 69%). Increasing Q0 from 0.25 to 0.5 NL/min (T = 1200 °C and Him = 120 mm) reduces XCH4 (19% vs. 9%). Doubling the melt height (Him from 60 to 120 mm) increases the residence time of bubbles, which increases XCH4 (7% vs. 19%). A customized sparger is also tested and shows little effect, probably because the holes are relatively large (1 mm diameter). An immersed bed of steel particles (0.2–0.4 mm diameter) instead shows improved results (XCH4 = 32%) at a relatively low temperature (1100 °C). Continuous reactor operation at 1300 °C without clogging is also confirmed. Analysis of carbon accumulated at melt surface during molten media methane pyrolysis reveals a tin-containing sheet-like structure.

Msheik, M., Rodat, S., & Abanades, S. (2024). Enhancing molten tin methane pyrolysis performance for hydrogen and carbon production in a hybrid solar/electric bubbling reactor. International Journal of Hydrogen Energy, 49, 962-980. https://doi.org/10.1016/j.ijhydene.2023.08.068