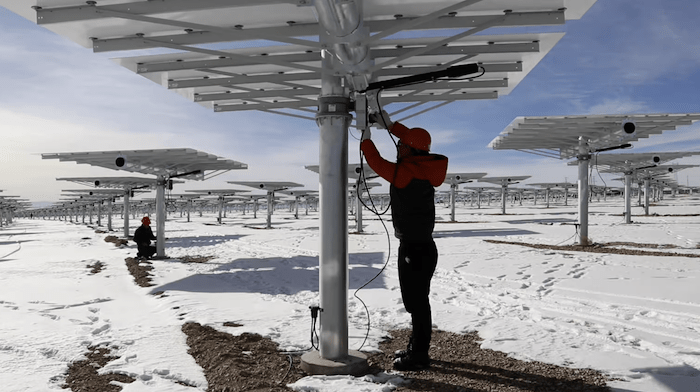

Supcon Delingha 50 MW tower CSP heliostat field during construction IMAGE@Cosin Solar

Known then as Supcon Solar, Cosin Solar developed two tower projects in China’s pilot CSP (Concentrated Solar Power) program; as technology and core equipment provider on PowerChina Gonghe 50MW tower CSP, and developing the Supcon Delingha 50MW tower CSP.

These were two of the five tower CSP demonstration projects that succeeded in China’s pilot program. Trough CSP had much lower success. As well as developing their own projects, Cosin Solar supplies tower CSP equipment, solar receivers, heliostats, solar field control systems, and automated cleaning vehicles.

In a long interview with Cosin Solar Chairman Jin Jianxiang, he explained the engineering solutions their team came up with for this form of CSP:

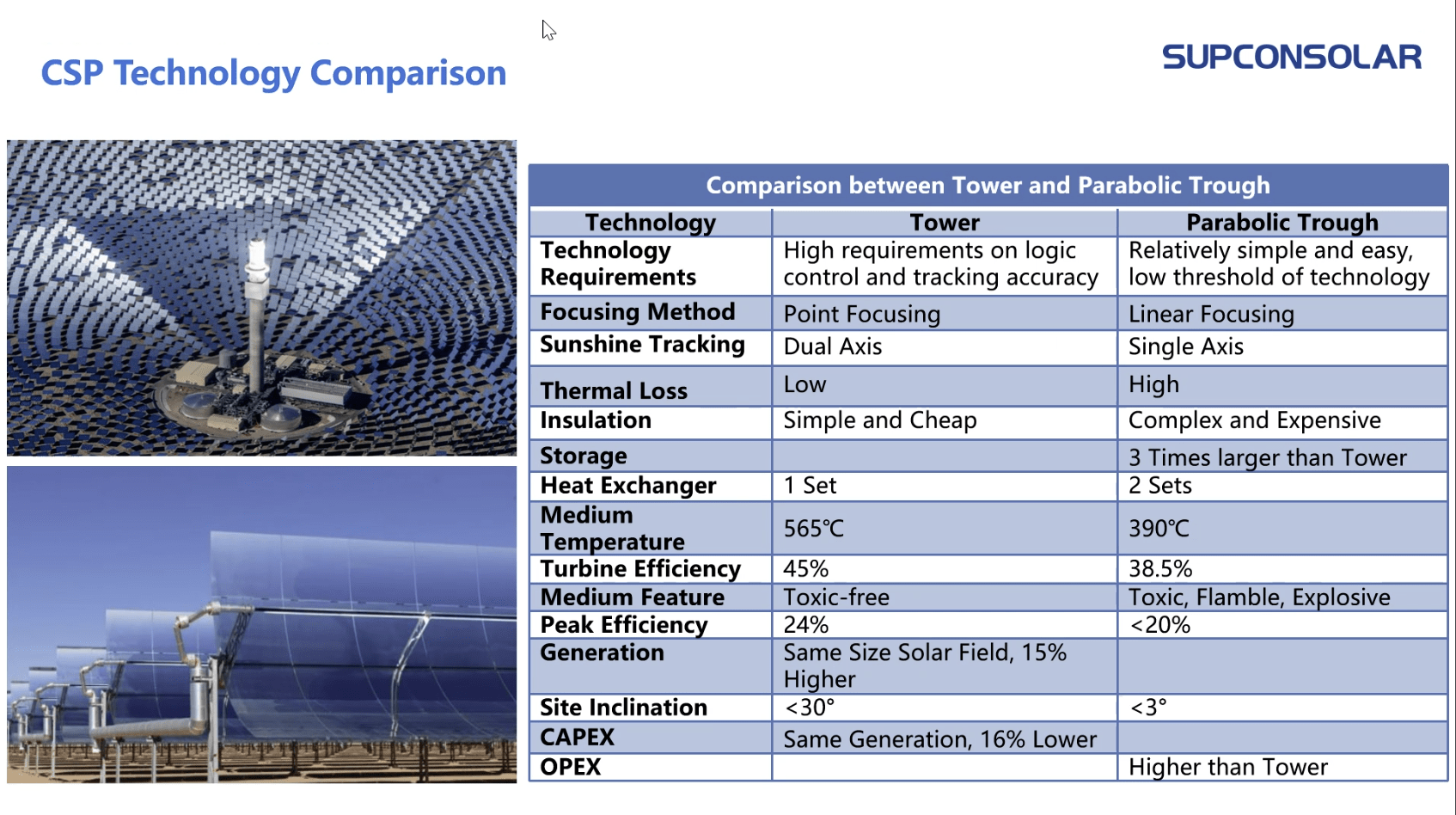

SK: Most of China’s new CSP underway for 2024 is tower. What was the advantage?

JJ: Tower has certain efficiency and cost advantages compared with parabolic trough, and has the good development opportunities as the new generation of CSP technology,

Tower CSP can heat the molten salt to 565℃, because it has a higher concentration ratio and directly uses molten salt as the heat absorption and storage medium. So tower can generate higher temperature superheated steam to drive the steam turbine, and we know that the higher steam parameters, the higher power generation efficiency of the steam turbine.

IMAGE@Supcon

SK: Did the high latitudes where the pilots were built also favor tower?

JJ: Yes, the advantages of building tower CSP plants in such latitudes was reflected in our monthly average power generation. Most of the high DNI regions in China are located in the middle and high latitudes where the sun altitude angle is small in winter, so the cosine efficiency of a parabolic trough collector solar field drops significantly with single-axis tracking. But for tower CSP heliostats, their dual-axis tracking is insensitive to higher latitude.

SK: And those high altitudes. Was that a challenge?

JJ: Our Delingha CSP plant is at an altitude of over 3,000 meters. The winter temperature is extremely low, reaching -35°C. There are more than 4 months construction downtime, and the low air pressure and sandstorms are a huge challenge to project construction management.

In response to the severe challenges posed by plateau hypoxia, low temperature and long winter downtime of project construction, we have adopted a reasonable planning and construction period, formulated strict project safety, health, quality and environmental protection requirements, flexible and reasonable prevention and rehearsal plans for common plateau diseases.

For project operation, the extreme low temperature at high altitude and high latitude, sandstorms and frequent cloudy conditions have brought huge challenges to the reliability of the equipment, the cleanliness of the heliostat field and the operation efficiency of the plant.

Through the complete product development and verification of the system, we have developed reliable tower CSP plant core equipment such as heliostats, receivers, which can operate stably in extreme plateau environments. After several years of the Delingha project operation, the reliability of these components has been proven.

We have developed a cleaning vehicle with automatic driving function, and deployed it with dry cleaning technology in a low temperature environment in response to the impact of the perennial wind and sand on the cleanliness of the heliostat field. For cloudy weather, we developed a cloud prediction system based on an all-sky imager, which provides a guarantee for the safe operation of the collection system.

SK: Was it difficult integrating your purely solar aspects; heliostats, solar receiver, AI controls, etc with the conventional thermal power block?

JJ: The integration of the heliostat field, thermal receiver, thermal storage system and power generation system is indeed a challenge. The key is matching parameters between systems and rational design of interfaces between systems and equipment, to ensure the design and product reliability meet the characteristics and operation mode of CSP plant.

SK: I imagine you chose suppliers experienced in traditional thermal power plants for non-solar components?

JJ: Part of your assumption is correct. We chose equipment suppliers with rich experience in coal-fired or gas-fired power for turbine generators, air-cooled units, etc.

But for thermal storage and exchange system, we select well-known suppliers in chemical manufacturing. Molten salt has been widely used in the chemical field before being used for CSP plants. Suppliers in this field are experienced in design, manufacture, and installation of molten salt equipment.

For the storage tanks, SGS and other equipment, our engineers participate in the design process, and entrust the work to top suppliers with rich experience in equipment design and production.

Through implementing multiple projects, we’ve developed a group of excellent suppliers of major components including glass, transmission part and steel structures, and helped suppliers to establish automated production lines to have the ability to mass-produce heliostats.

However, with the current early development scale of CSP, there is still a gap compared to the supply chain of PV modules. With industrial scale development, there’s room to further reduce cost of the main CSP components.

SK: Why did you choose medium size heliostats – 20-30 square meters – over the larger ones?

JJ: Because their high assembly efficiency and fast installation speed greatly shorten construction and solar field commissioning time over large 100 square meter heliostats that require large mechanical controls, leading to low installation efficiency and safety. Our parallel calibration based on image recognition increases calibration efficiency, shortening commissioning times dozens of times over large heliostats.

During operation, wind pressure is much smaller than on large-sized heliostats. So working wind speed is higher. And medium-sized heliostats can be cleaned by automated cleaning vehicles, while most large-sized heliostats are cleaned by manually driven vehicles. So daily maintenance cost is lower.

SK: How do you stop too-intense solar flux from burning out the receiver?

JJ: During design, we fully consider expansion and stretching at different positions caused by uneven energy in partly cloudy and other weather. Permanent deformation of the receiver in harsh working conditions can be avoided by structural optimization.

Our heliostat tracking accuracy and heliostat optical accuracy are the leading level internationally, so we can ensure uniform facula on the surface of the receiver and reduce receiver deformation risk under normal operating conditions.

We monitor the outer wall temperature of the receiver with equipment such as infrared cameras. Through intelligent pipe blocking detection, an over-heat detection algorithm and automatic energy scheduling strategy, we detect abnormal working conditions; protecting the receiver.

Our automatic operation scheme also reduce the thermal shock and deformation risk under the cloudy weather through high-precision cloud prediction system and automated cloudy condition processing strategy.

SK: Thermal storage tank leaks seem to be a risk with tower because of its extreme temperatures. Yet I hear you’ve had no problems?

JJ: We have some innovative designs to prevent the leakage of storage tanks. We have carried out the whole process control from design, construction and operation.

In the design, the tank body should not only meet the strength design safety, but also consider the influence of fatigue, stress corrosion and other factors on the lifetime, and reduce the maximum stress level of the tank. For example, we can reduce the peak stress of the tank floor by more than 40% through our design optimization.

Most storage tank foundations of CSP projects are ceramsite foundations. We adopt composite insulation foundations, which can reduce the risk of uneven settlement of storage tanks and improve the insulation effect of foundations. For the anti-condensation measures of the storage tank, other projects basically adopt the electric heater inserted into the side wall,. But too many openings in the side wall of the storage tank will increase the risk of leakage, so our anti-condensation design plan is to arrange a set of automatic control electric heat tracing system in the tank and the bottom of the tank.

The construction process is strictly controlled. The welding groove and non-destructive testing report are issued (the designer will participate in the report review in the whole process) and unqualified welds shall be reworked. For example, the bottom plate of storage tanks in the world generally adopts the lap joint method, but our bottom plate adopts the butt welding with 100% radiographic inspection.

Then to prevent thermal shock during operation, we have designed a set of interlocking control logic to strictly control the maximum temperature difference in the storage tank.

All of these measures reduce those risks.

This was Part II of a very, very long conversation to catch up on CSP developed in China.

Part I is here.