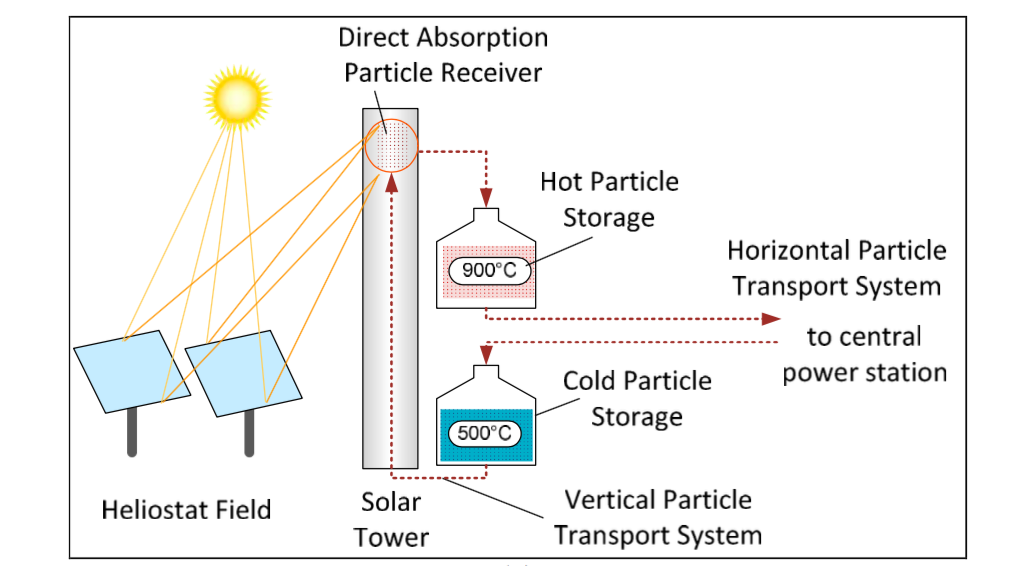

The tower form of Concentrated Solar Power (CSP) is very young technology. Less than a gigawatt is deployed globally, making it a nascent technology at the “Cambrian explosion” stage; multiple innovations are still being explored to cut costs. (How tower CSP works)

A new economic study looks at reducing its Levelized Cost of Electricity (LCOE) through the use of a thermal storage medium that is capable of a wider temperature range than molten salts – the current state of the art storage fluid used in tower CSP. (How CSP thermal storage works)

Molten salts are liquids at the temperature range used in CSP for thermal storage (a cold of 290C°C to a hot of 565°C). They must not become colder or they solidify, or hotter as they decompose, so the temperature range within which they can operate at between these extremes is less than 300°C.

Instead, the study; Solar Tower System Temperature Range Optimization for Reduced LCOE investigates the effect on LCOE of a heat transfer material (HTM) that has a wider working temperature range of 600°C between minimum and maximum heat. Bauxite particles, a gritty sandlike material – that’s readily available because it’s used in natural gas drilling – remains stable at temperatures as high as 1,000°C.

With an operating range between 400°C and 1,000°C, bauxite particles could double the 300°C operating range of molten salts to 600°C. Study author, Reiner Buck, Head of Solar Tower Systems at the DLR Institute of Solar Research analyses the possible LCOE reduction of a novel setup allowing this wider HTM temperature range.

Bauxite particles IMAGE @Reiner Buck

Bauxite particles would be trucked to the power block

Despite the temperature advantage of particles for HTM, the disadvantage is that they are heavy and must be shoveled around mechanically. So a great deal of international research – at research institutions in the US, in Germany, and in Saudi Arabia, among others – is going into ways to move particles mechanically

Buck proposes multiple 50MW towers serving one central power block. Instead of using pipelines from each tower for sending the HTM to the central steam cycle power block a kilometer away – he envisions simply transporting the particles between the towers and the power block in insulated containers driven back and forth on autonomous trucks.

A set of three containers would be used for the transport of hot particles: so that at the same time one could be being filled at the solar tower module, another one would be being transported, and the third container would be discharging the hot particles at the central power block. A similar set of three containers would be used for the cold particle transport. Depending on the required mass flow, a truck could serve one or multiple solar tower modules.

“Using trucks carrying insulated containers is probably the most efficient and less costly option,” Buck explained. “You can imagine if you use piping to transport 1,000°C particles over this distance of 1 kilometer between the 14 towers and the power block you can lose a lot of energy: You would need an enormous amount of insulation to do this efficiently, and with the pneumatic transportation you also need to have the power for the compressor.”

Researchers have previously investigated a multi-tower setup with molten salt storage, but this was found to offer no advantage, because transporting a liquid along insulated piping would add such high costs, negating any efficiency gain. Instead, only the containers on the autonomous trucks would be insulated.

CSP is already a fairly “laborious” solar technology compared to the simplicity of PV that has its “magic” already manufactured within simple panels, and this multi tower CSP concept does not shy away from (mechanically) labor-intensive solutions. But Buck notes that traditional heavy industries are just as laborious. Indeed, the oldest thermal form of electricity burns heavy clumps of coal which must often be transported thousands of miles across continents by rail.

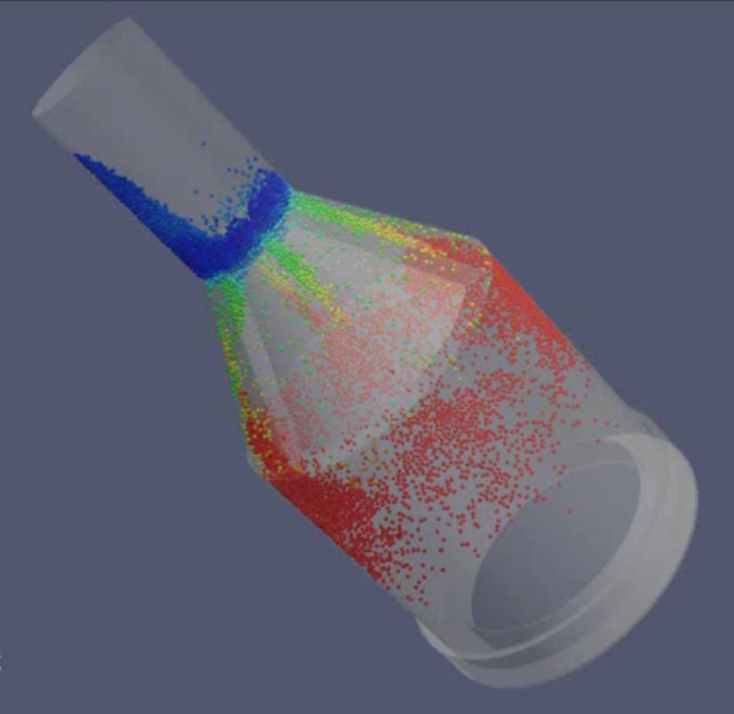

CentRec rotating receiver IMAGE @DLR

Lifting the particles to the CentRec receiver

Atop each tower, there would be the rotating centrifugal receiver; “CentRec®” that Buck and his team developed at DLR to reach very high temperatures with particle technologies. CentRec has a rotating chamber like a cement mixer, exerting centrifugal force to keep the particles in motion along the chamber wall, while being exposed to the solar flux from below.

Buck noted a size limit: “We think with this type of rotating receiver we can build receivers up to a power level of 50MW but not more. Eventually we can go bigger, but this is not known yet.” CentRec’s single opening means its heliostat field is not circumpolar, but is arrayed only in front of the receiver.

“The surround field is an optimal configuration if you have a molten salt receiver, but has some drawbacks with field efficiency and receiver efficiency. We use a cavity receiver and there the optimum field configuration is one-sided,” he said.

To hoist the bauxite particles up each tower to be heated in the receiver, Buck is agnostic between two popular lift systems that are standard in the mining industry. “There are different options. There is the option of using a mine hoist system. This is one of the options which is followed by many of the R&D teams who are working on particle systems,” he said.

Bucket elevators are the other well-tried possibility: “You will take the system which has the lowest cost and the lowest heat losses. It is a question of cost and performance optimization, but not critical because it is a relatively small amount of the total investment.”

The advantage of 1,000°C particles with a 620°C steam cycle

Most particle research is intended for pairing a particle system with a high temperature supercritical CO2 power cycle. For example, the US DOE is aiming to raise power cycle efficiency to over 50% by switching to a s-CO2 power cycle at 715°C. Buck would pair bauxite particles with a steam cycle that can operate at up to 620°C.

Why pair super high temperature particles with lower temperature steam? Buck’s wry observation, having researched both s-CO2 and the most efficient steam cycle, is that the advantage lies in the fact that the 620°C steam cycle “exists”.

“So the real answer to how does s-CO2 compare is: “Nobody can tell you right now,”” he laughed. “There are no reliable cost figures for s-CO2, because these systems simply do not exist on the market. They are currently under development, and some people have high hopes that they will become as efficient as some people claim and as cheap as some people claim.”

For either power cycle, steam or s-CO2, his LCOE research would be applicable, as the power cycle temperature is in the same range. “In the paper I did on s-CO2, the cycle temperature is 600°C, about the same as the steam power cycle, so the temperature levels and pressure levels are comparable between the steam cycle and the s-CO2 cycle. So for the system optimization of the solar system especially, it wouldn’t make a big difference,” he pointed out.

The results?

Buck’s analysis evaluated impact of the increased temperature span of the particles on the LCOE. The results of this doubling of the operating range of molten salt tower CSP, using bauxite particles with a multi tower operation are seen in this graph. The curved lines show the benefit of increasing temperature ranges, assuming ‘cold’ of either 400°C or 500°C temperature of receiver at inlet (Tr,in) and the greater the range, the lower the LCOE.

The greatest benefit to LCOE is when the temperature range is the full 600°C (between a low of 400°C and 1000°C) shown bottom right in green, and this maximum range is only possible if the ‘cold’ temperature of the receiver at inlet (Tr,in) starts at a low of 400°C. IMAGE@Reiner Buck

When the (green) temperature of receiver at inlet (Tr,in) starts at 400C cold but can merely heat up by 300°C (to 700°C) the LCOE is 6.1 EU cents, but at the maximum 600°C range, this is reduced to nearly 5.6 EU cents.

While costs of solar field and receiver get higher with temperature span, the storage and steam generator costs are measurably reduced IMAGE @Reiner Buck

“You see a certain increase in heliostat field cost, because receiver efficiency and heliostat field efficiency go down with higher temperatures, therefore you need to add some heliostats,” Buck commented. “But in the end, combining all this together, the total investment goes down significantly. And this is what leads to the reduced LCOE.”